Category

- Laser Marking Machine

- Fiber Laser Marking Machine

- UV Laser Marking Machine

- Laser Engraving Machine

- Mini Laser Engraving Machine

- Laser Cutting Machine

- Plasma Cutting Machine

- CNC Router

- Metal CNC Router

- Woodworking CNC Router

- Machine Spare Parts

- Laser Machine Parts

- CNC Machine Parts

- Laser Welding Machine

- CNC Knife Cutting Machine

- Fiber Laser Cutting Machine

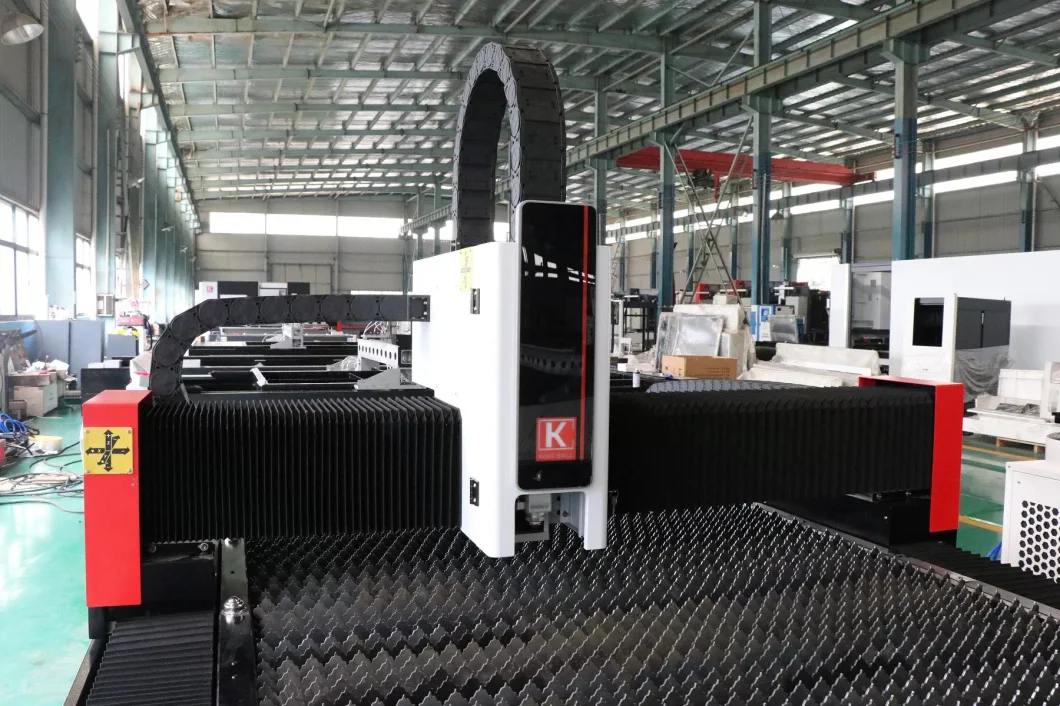

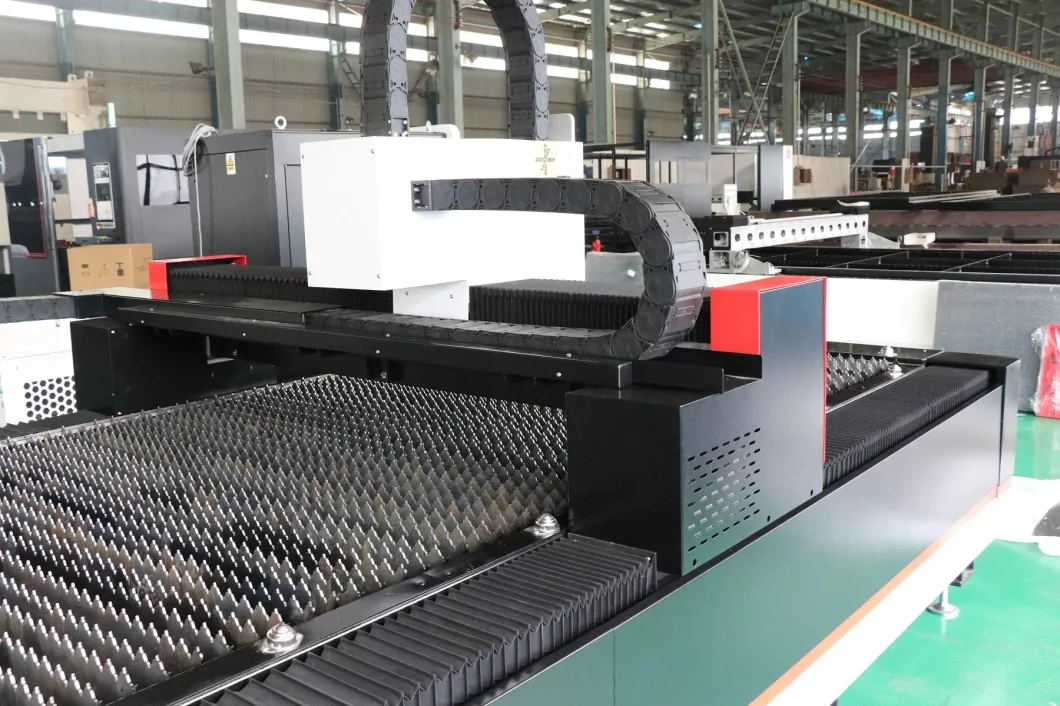

Fiber Laser Cutting Machine of Kingball

Products Description Performance. Professional mechanical design, novel appearance modeling and a number of patented tec

Basic Info

| Model NO. | KCL |

| Application | Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Applicable Material | Metal |

| Structure Type | Desktop |

| Laser Classification | Solid Laser |

| Laser Technology | Laser Flame Cutting |

| Jiangsu | Nanjing |

| Transport Package | Plastic |

| Specification | KCL |

| Trademark | KINGBALL |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 100 P/M |

Product Description

Products Description

Performance.

Professional mechanical design, novel appearance modeling and a number of patented technologies, with high degree of refinement, fast speed, small cutting seam, smooth section, simple operation and low energy consumption, are suitable for mass continuous processing and highlight the cutting competitive advantage.

| Model | KCL-3015 | KCL-4015 | KCL-4020 | KCL-6020 | KCL-6025 | KCL-8025 | KCL-10025 | KCL-12025 |

| Cutting Range (mm) | 3000*1500 | 4000*1500 | 4000*2000 | 6000*2000 | 6000*2500 | 8000*2500 | 10000*2500 | 12000*2500 |

| Laser Power (w) | 1000W&1500W&2000W&3000W&6000W&8000W&12000W | |||||||

| Maximum idle speed | 160 m/min | |||||||

| Maximum cutting speed | 35-80 m/min | |||||||

| Positioning Accuracy | 0.03 mm | |||||||

| Reposition Accuracy | 0.02 mm | |||||||

France MOTOREDUCER Servo Motor-Japan FUJI

Hanli brand Industrial chiller Electric cabinet(Separate electric cabinet with air conditioning)

Air Compressor(Optional) Volatge Regulator(Optional) Dust Extraction System(Optional)

Our Service

Pre-sales services:

1. inquiry and consulting support 2. sample testing support 3. visit our factoryAfter-sales services:

1. 2 years warranty period 2. training how to install and use the brake press machine 3. engineers available to service machinery overseasContact WaysMr.Pumbaa YangCustomer ManagerE-mail:[email protected]

FAQ

1.Can you supply the relevant documentation?Yes, we can provide most documentation including Certificates of Analysis/Conformance; Insurance; Origin, and other export documents where required.2.What is the average lead time?For samples, the lead time is about 7 days.For mass production, the lead time is 20-30 days after receiving the deposit payment.The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try toaccommodate your needs. In most cases we are able to do so.3.What kinds of payment methods do you accept?You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.Or irrevocable LC at sight.4.What is the product warranty?We warranty our materials and workmanship.Our commitment is to your satisfaction with our products. In warranty or not, it is theculture of our company to address and resolve all customer issues to everyone's satisfaction.5.Do you guarantee safe and secure delivery of products?Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.6.How about the shipping fees?The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way.By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details ofamount, weight and way. Please contact us for further information.